Extending the Life of Trucks, Trailers, and other Metal Assets – Cleaning and Corrosion Protection

To some, metal assets dictate livelihood. Truck drivers, for example, depend on the structural integrity of the vehicle for both income and personal safety. Maintaining the truck is extremely important, and can often require the replacement of parts. This can be very costly, especially in a sometimes volatile industry.

To some, metal assets dictate livelihood. Truck drivers, for example, depend on the structural integrity of the vehicle for both income and personal safety. Maintaining the truck is extremely important, and can often require the replacement of parts. This can be very costly, especially in a sometimes volatile industry.

Other people invest in metal structures that serve more recreational purposes. A boat trailer, for example, may not get use all year long, but its structural integrity does protect not only the boat, but also anyone on the road with it when it’s being towed. Safety aside, trailers aren’t cheap, so clearly any owner would prefer it lasts as long as possible.

These kinds of vehicles and equipment spend a lot of time in the elements, so they’re extremely vulnerable to corrosion. Of course, corrosion isn’t just unsightly. It can destroy metal and electrical components, making them unusable or worse, unsafe.

When it comes to something like, say, an aircraft, routine cleaning is mandated because of the destructive effects of corrosion. Cleaning metal and electrical components removes the substances that cause corrosion, thereby extending the life of the parts. It also serves as an opportunity to inspect and remove any corrosion that has occurred.

However, the cleaning itself can lead to corrosion as well, especially for hard-to-reach places. That’s why in the case of an airplane, cleaning products that contain corrosion inhibitors are extremely valuable. Corrosion protection is also a necessity when cleaning electrical components. The cleaning process itself leaves the components susceptible.

In some cases, when metal is cleaned, residues of oils and emulsion can mix in with solvent that hasn’t drained away from the metal. Or it mixes in with the cleaning bath. When modified alcohols and hydrocarbons are used, these residues can increase the acid content of the solvent, which can potentially cause corrosion. This would necessitate a corrosion inhibitor being applied after the cleaning process rather than during.

The truck or trailer owner may not depend on clean surfaces to keep from falling out of the sky, but it certainly impacts both safety and pocketbook. Consider how many metal parts make up a semi-truck and what they cost to replace: brake shoes and drums – $700; fuel tank – $750; radiator – $1400. As for replacing the trailer, hopefully you don’t learn the hard way when it does need replacing or you’re also looking at the cost to repair or replace your boat.

Ultimately, the easiest, most cost-effective means of stretching your dollar and extending the life of these assets is to both clean and protect the metal. Depending on the application, you can find corrosion inhibitors that stand alone or that are part of the cleaning or degreasing solvent. By cleaning regularly and using a corrosion inhibitor, you literally save thousands of dollars, potentially over the course of just a year.

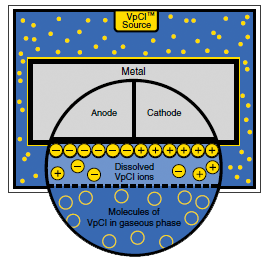

Packnet carries a full line of VpCI cleaners, degreasers, and rust/oxide removers for metal. The applications vary from aircrafts to screws. VpCI is the safest, most effective product on the market. Contact us for more information on how to protect your metal assets: 952-944-9124 or email [email protected]