Solving complex crating issues in unique ways

There is almost no limit to the unique custom packaging and crating solutions that Packet devises to meet specific needs. In one case Packnet designed and built humidity controlled crating system.

The client was Standby Systems, producer of high-performance equipment and services to energy producers, gas and liquid transmission pipelines, natural gas distribution utilities and industrial/commercial gas consumers of every size.

The Challenge

Standby Systems had a unique client situation that required a fast, but well devised solution. The company’s eastern USA utility suffered delays in a project which involved multiple pieces of large, custom process equipment made by Standby. A revised schedule required equipment to be stored outside in the elements for nine or more months after shipping it until contractors would be able to install it. This was the best and least expensive option for the client instead of renting a warehouse large enough to store multiple pieces. The decision was made to fully crate the equipment before shipping, but there was still a concern over how to protect the mainly galvanized steel equipment for outside storage. Standby suggested tarping it, but their client wanted stronger protection. The client was willing to invest in extra measures to ensure the equipment was protected.

Packnet has been involved in a number of projects where equipment is stored in hostile environments for extended period of times. Preventing corrosion is the primary concern.

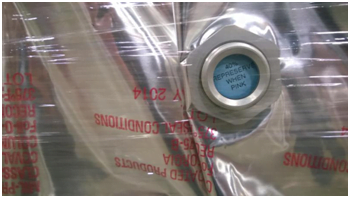

Packnet suggested adding humidity control to the crates with a design that would monitor the moisture levels and provide safekeeping of the contents, which in turn would give Standby’s client extra assurances. By the time Packnet was finished, 11 very large pieces of equipment were packed and secured including a couple of tanks too tall to ship vertically, so Packnet designed cradles for them. In the end, an ideal packaging solution was created and implemented that resulted in the protection of costly equipment and highly satisfied clients all around. The system that Packnet developed was a set of enclosed crates that used precise amounts of desiccants to keep moisture down. The proper amount of desiccant required is based on cubic volume and other considerations. Humidity plugs were installed for monitoring. They are sensors that are visible and turn pink when a 40% threshold has been experienced. The sensor is on inside of bag, while viewing window is external. It’s a two part gasket with threads that screw together.

Packnet suggested adding humidity control to the crates with a design that would monitor the moisture levels and provide safekeeping of the contents, which in turn would give Standby’s client extra assurances. By the time Packnet was finished, 11 very large pieces of equipment were packed and secured including a couple of tanks too tall to ship vertically, so Packnet designed cradles for them. In the end, an ideal packaging solution was created and implemented that resulted in the protection of costly equipment and highly satisfied clients all around. The system that Packnet developed was a set of enclosed crates that used precise amounts of desiccants to keep moisture down. The proper amount of desiccant required is based on cubic volume and other considerations. Humidity plugs were installed for monitoring. They are sensors that are visible and turn pink when a 40% threshold has been experienced. The sensor is on inside of bag, while viewing window is external. It’s a two part gasket with threads that screw together.

Prevention of corrosion during long term storage can involve several strategies. Packnet has also used the Cortec VpCI product in other cases. These products can come in the form of plastic wraps, emitters, or coated paper. The Cortec VpCI emits ions in a vapor pressure; the ions seek out metal surfaces and bond to them, creating a highly corrosion resistant barrier. Custom shrink wrapping is another method Packnet has employed.

Packnet has the engineering expertise and experience to solve unique packaging and storage problems that the competition can’t handle. If you have a unique packaging, crating or storage challenge in an industrial application, please contact Packnet at (952) 944-9124 to speak with a knowledgeable representative.